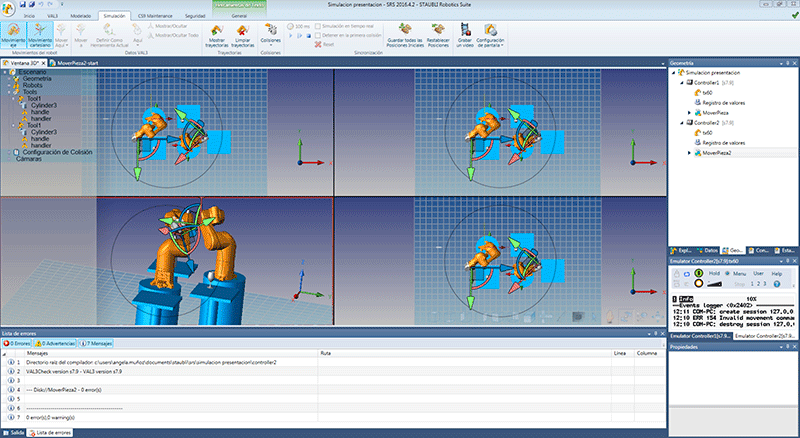

Increasingly, robotic systems are subject to more demanding conditions of accuracy, speed and reliability. The previous analysis of the application through computer simulation will allow us to anticipate design errors and improve the overall operation of the robot.

The off-line simulation software allows to graphically displaying the operation of a robotic production system, covering different operations, such as welding, assembly, painting, molding, part classification, artificial vision, etc.

By means of this tool we can carry out the following tasks before the start-up:

- Simulation of operations with multiple robotic arms

- Calculation of trajectories, speeds and production times

- Collision detection, estimation of minimum and maximum ranges, and definition of safety zones

- Optimal selection of robot characteristics for each application

- Study of robotic cells, from the import of pre-designed 3D models

If you are interested in our ROBOT SIMULATION services and / or need more Information, contact us or visit us at our offices.

CAD DESIGN AND MODELING

Creation of three-dimensional models of mechanical parts and assemblies for industrial machinery.

TECHNICAL DOCUMENTATION

All the necessary documentation for the manufacture of toolings and mechanical parts and assemblies.

OFF-LINE ROBOT SIMULATION

Production planning with calculation of cycle times and ranges, visualizations of design errors, and many other applications.

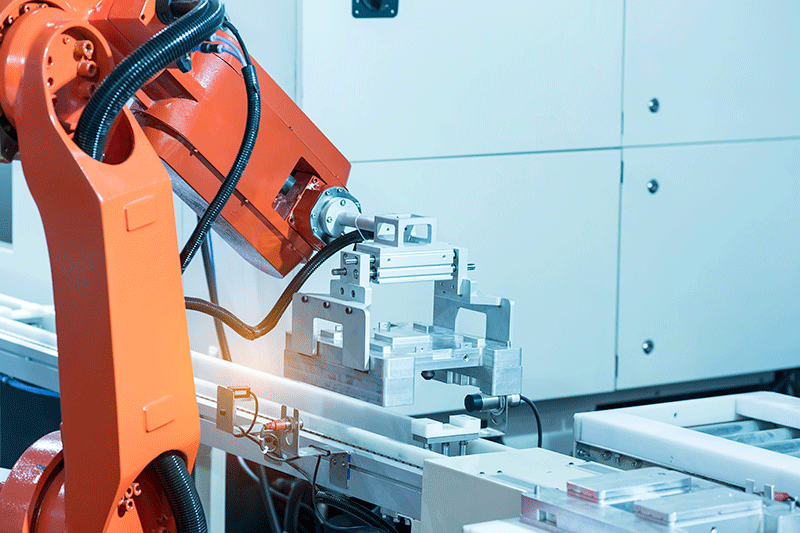

INDUSTRIAL PROCESSES

Testing and consulting of processes, commissioning of equipment, set-up of industrial processes.